Drones Are Entering Into Warehouse Management

What is that buzzing and humming sound ? This is a question that many warehouse visitors will be asking in the not so distant future. What will be...

3 min read

Chadwick Heard

:

Updated on June 26, 2024

Chadwick Heard

:

Updated on June 26, 2024

Smart vests are being designed to monitor and personalize the training of elite athletes. What if the same technology could be applied to warehouse workers? Imagine how this could impact the logistics industry. Let's dive into the implications of this new tech, and how it could be applied.

We found an interesting article in the IoT Journal that discusses the usage of smart vest technology for professional athletes. The first test run was applied to the athletes of Ireland's Gaelic Athletic Association. They're currently testing out a sensor-equipped vest made by the Canadian company Hexoskin, with sensors provided by Analog Devices.

This, in combination with a Microsoft-based data analysis program, is used to help coaches personalize the training regimen of individual players based on what the data tells them.

How cool is that?

This technology allows the coaching staff to get the best results out of each player, which helps the entire team work better as a whole.

Microsoft's Azure IoT cloud-based analytics engine collects and analyzes the data transmitted from the vests. This provides coaching personnel with insights into player performance, injuries, and possible abnormalities.

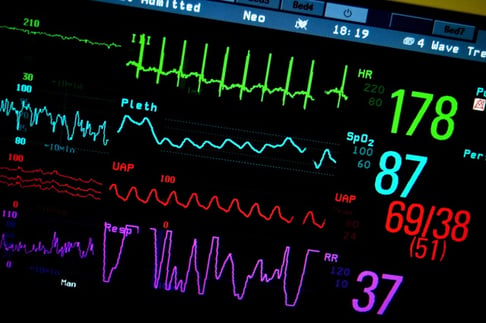

The vests contain an ECG heart-rate monitors, as well as an Analog Devices accelerometer that is used to record the player's movements and respiration rate, tracking the number of times the chest cavity expands and deflates per minute.

A Bluetooth radio integrated into the vest transmits the data to a paired Bluetooth-enabled smartphone, tablet, or computer. The sensors can run for roughly 14 hours before they need to be recharged via a USB cable.

Jason Lynch, Director of IoT Strategy at Analog Devices, says that Hexoskin and partnering companies believe the vest will provide a new level of visibility to professional team managers.

We all know that visibility is a key component to the supply chain. What kind of visibility could this sort of technology provide to warehouse managers? Exploring these possibilities is a great opportunity for logistics professionals to get creative with potential efficiency solutions.

Here are a few ways that we think this type of technology could be used in the logistics industry:

Have you ever been in a warehouse during extreme weather conditions (hot or cold)? Many warehouses are not heavily insulated. These large open spaces can often turn into iceboxes or ovens, depending on the outside climate. If not monitored carefully, this can turn into a dangerous environment for warehouse workers. OSHA has regulations in place to make these types of weather conditions safer for workers. Imagine if you could monitor the heart rates of workers wearing these vests. Alerts could be set up that would flag workers whose heart rates were approaching dangerous levels.

Damaged product, damaged equipment, and injury to workers is often caused by fatigue. These costs can add up fast and disrupt the flow of an operations. Warehouse and transportation workers often face very demanding situations to load, unload, or store product while keeping up with a steady workload. For these reasons, it is necessary for managers to monitor fatigue and its impact on their employees. Often workers will continue with their tasks without taking breaks for rest. Sometimes they aren't honest with themselves or their managers about their level of fatigue.

This is where the smart vest could come into the equation, making operations run smoother. The sensors on this vest would allow managers to monitor fatigue more closely, rotating workers in and out to get the job done efficiently, while reducing the chance of worker injury.

The smart vest also has the ability to monitor the activity of the person wearing it. Naturally, there are going to be some employees that make more of an effort than others. This data could give managers key insight into which workers are the most active and determine the workload of each staff member. For example, if a manager sees that one employee is working much harder than the rest, they can adjust the workload. This prevents the hardest worker from getting too burned out, ultimately allowing for a more efficient usage of labor and increased productivity.

Here is the article that inspired this post if you want to read up on it.

Smart Vest Could Be Key to Improving Athlete Health, Performance

At RBW, we aim to maintain safe working enviorment for our employees by keeping up with OSHA standards. We are able to do this by efficiently allocating our labor without sacrificing productivity and quality.

What is that buzzing and humming sound ? This is a question that many warehouse visitors will be asking in the not so distant future. What will be...

There are many changes happening in the logistics industry today. With some of the changes that are coming in the future, companies must start...

No doubt you've heard plenty about smart devices, but you probably haven't heard a lot about smart stores and how they're changing the way supply...