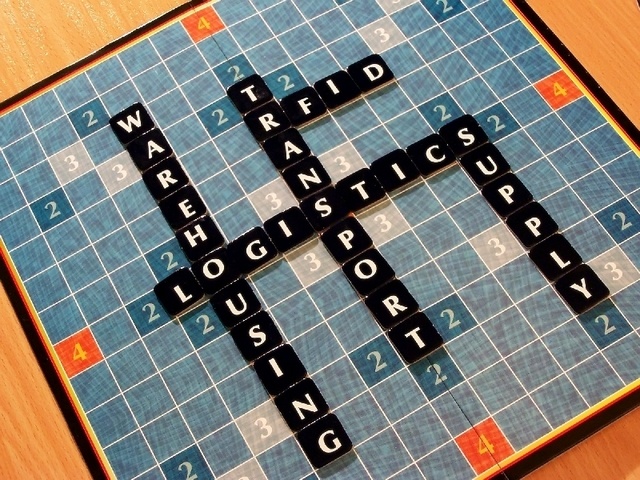

The 5 Biggest Supply Chain Challenges

Supply Chain Challenges Supply chain managers have seen increasing challenges to create, and keep, efficient and effective supply chain methods....

1 min read

Tim Brittingham

:

Updated on October 27, 2017

Tim Brittingham

:

Updated on October 27, 2017

Supply and demand is constantly changing, even on an hourly level. This can be hard even in traditional markets and supply lines, but the growing demand for same-day delivery with two-delivery as the default maximum means you have to have the supply available both locally and immediately. In order to use an omnichannel supply chain model effectively, you need two key streams of data: inventory and anticipated sales.

Changes in the way companies distribute their goods and do business are happening every day. An omnichannel supply chain is just one of those changes, and it's one of the best ways for physical stores to stay competitive with online shopping.

Supply Chain Challenges Supply chain managers have seen increasing challenges to create, and keep, efficient and effective supply chain methods....

How Do I Sell The Value of Good Supply Chain Management ? The Supply Chain gets products manufactured and distributed into the hands of the...